FDM 3D printing

You are here » Home »

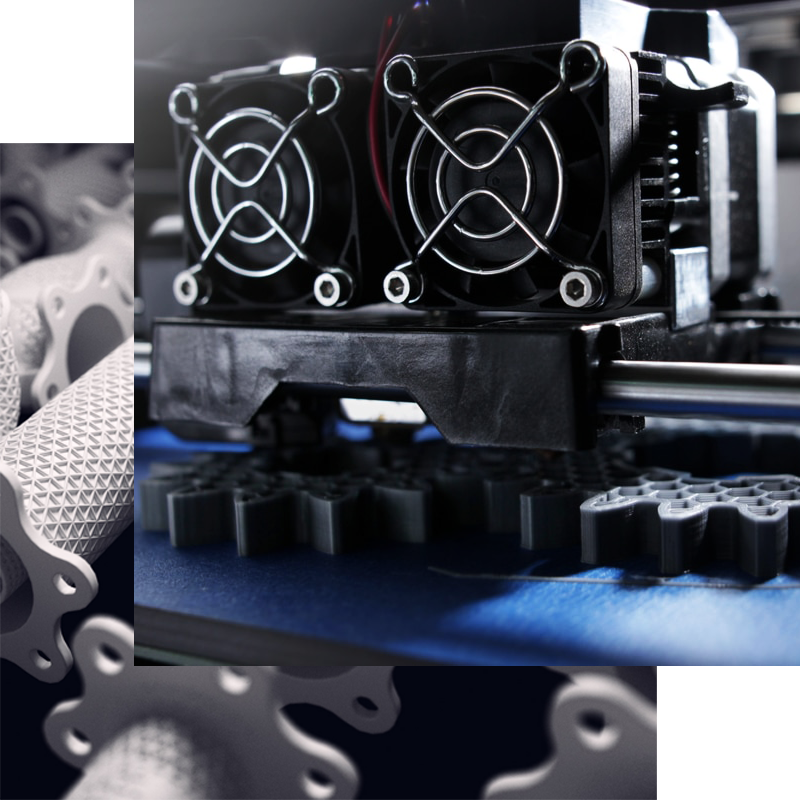

Discover FDM 3D printing technology

As you have read on the 3D Printing page, there are 3 main categories of 3D printing technologies: FDM, SLA, SLS.

Here, we will explain FDM 3D printing.

FDM stands for Fused Deposition Modeling.

This technology of 3D printing is more democratized, its principle is quite simple: a thermoplastic filament is melted and then extrude layer by layer to manufacture the parts.

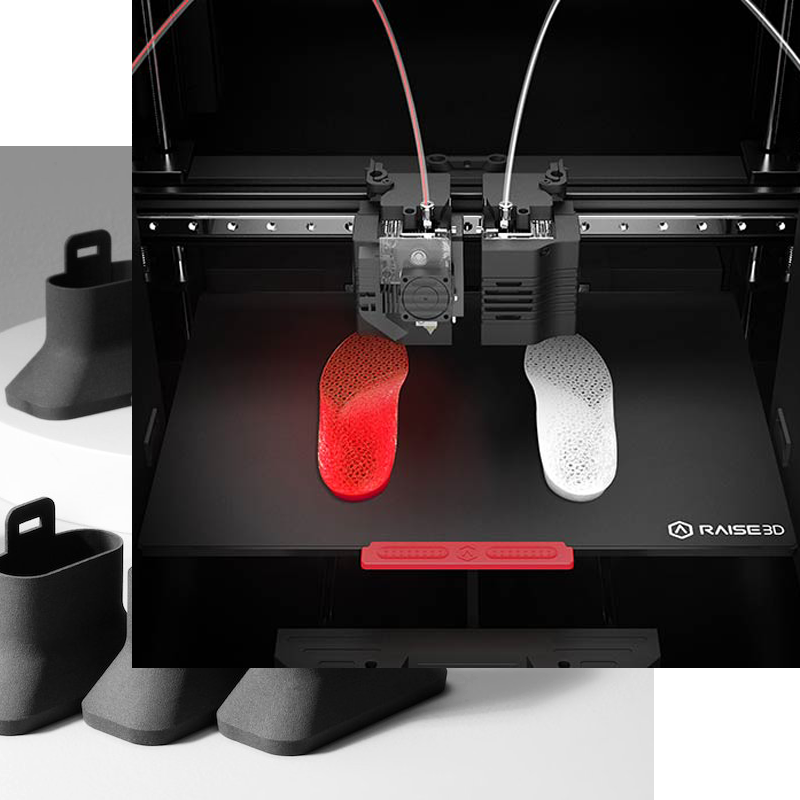

One of the big advantages of FDM printing is that it allows the use of a wide variety of materials such as ABS, PLA, NYLON, flexible materials and hybrids (wood, copper), which allows the manufacture of functional parts meeting mechanical constraints.

The resolution and accuracy of FDM printers are lower than SLA and SLS printers, but we have a printing capacity of up to 50 microns, which allows us to obtain excellent results.

Advantages of FDM 3D Printing

- Wide choice of materials

- Mechanical properties of the printed parts

- Price

Disadvantages of FDM 3D Printing

- Lower resolution than SLA and SLS

Ideal application for FDM 3D printing

FDM printing is perfect for demonstrating the feasibility of your part, for your first prototypes or even for the production of small series of parts with a simple and medium complexity level. If precision and surface finish are a priority, we recommend SLA 3D printing.

To print a 3D object with FDM technology, you can use our FDM 3D printing service.

Example of FDM Printed Parts