SLA 3D printing

You are here » Home »

Discover SLA 3D printing technology

As you have read on the 3D Printing page, there are 3 main categories of 3D printing technologies: FDM, SLA, SLS.

Here, we will explain SLA 3D printing.

SLA stands for Stereolithography. Like FDM technology, SLA is an additive manufacturing method: parts are manufactured by successive application of layers. However, the 2 technologies use different processes.

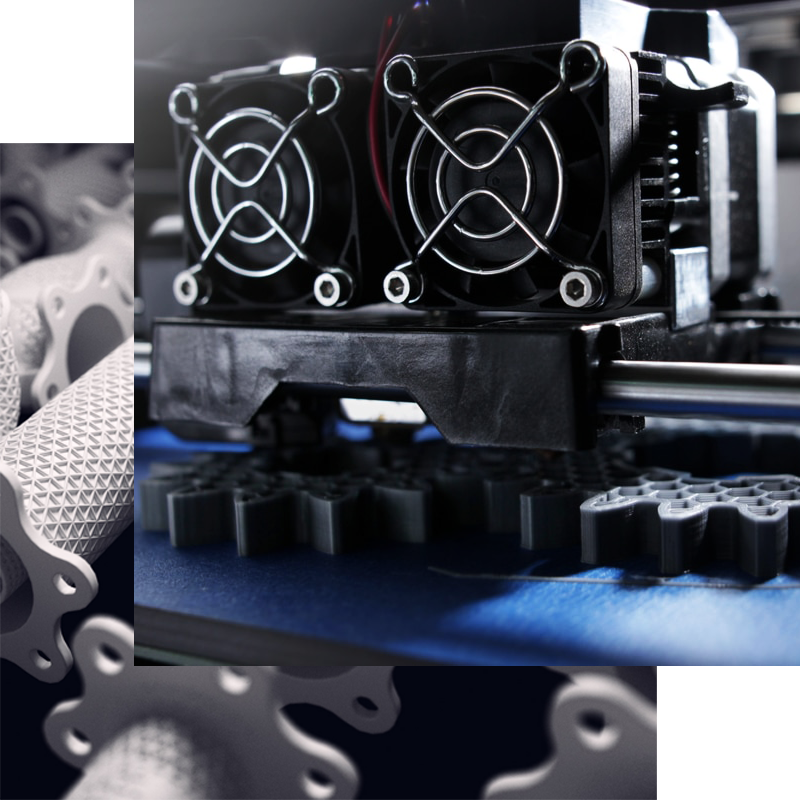

FDM uses a thermoplastic filament that is melted and deposited layer by layer, while Stereolithography (SLA) is based on the photopolymerization process.

A photosensitive resin is polymerized (solidified) by a light (laser or projector) layer by layer until the final object is obtained.

SLA 3D printers allow the manufacturing of objects with higher resolution and are more precise than FDM 3D printers. This accuracy is achieved because of the tiny size of the laser’s optical point. In addition, with stereolithography, less force is exerted on the parts during printing, which promotes smoother surfaces than an FDM printed model.

Advantages of SLA 3D Printing

- Better resolution and accuracy than FDM 3D printing

Disadvantages of SLA 3D Printing

- Less materials and colors available

- Higher costs than FDM

- Smaller print size than 3D FDM printing

Ideal application for SLA 3D printing

SLA printing is recommended when the object to be printed contains very fine details, where precision and surface finish are a priority. Stereolithography is widely used in the dental and jewelry industries for the manufacture of molds (silicone or other) but also for the creation of figurines.

If your part must meet mechanical constraints (in an assembly for example), we recommend FDM 3D printing. If, on the other hand, you need high precision for small objects, we recommend our SLA 3D printing service.

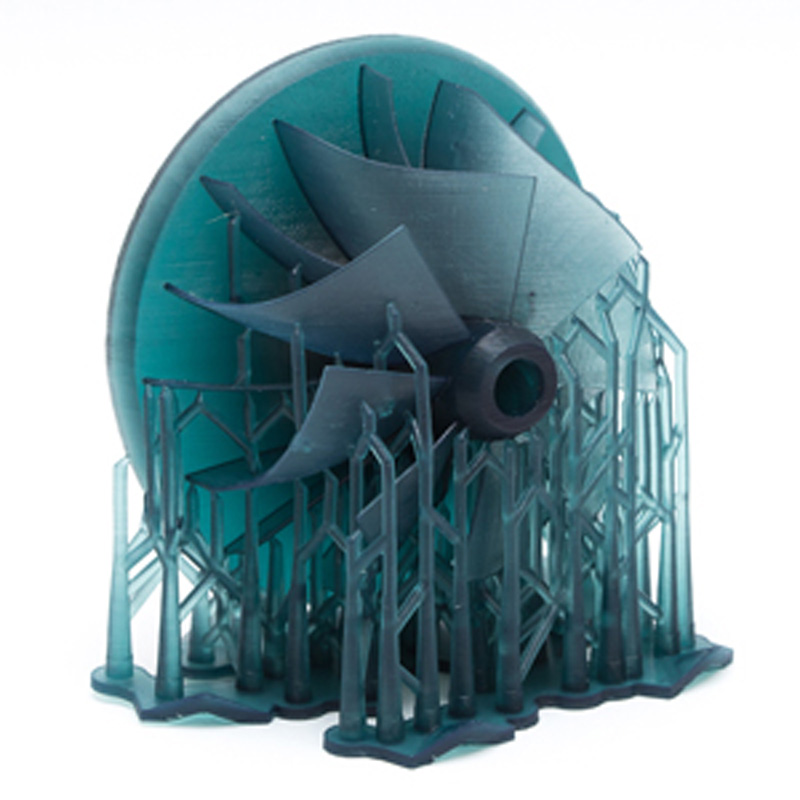

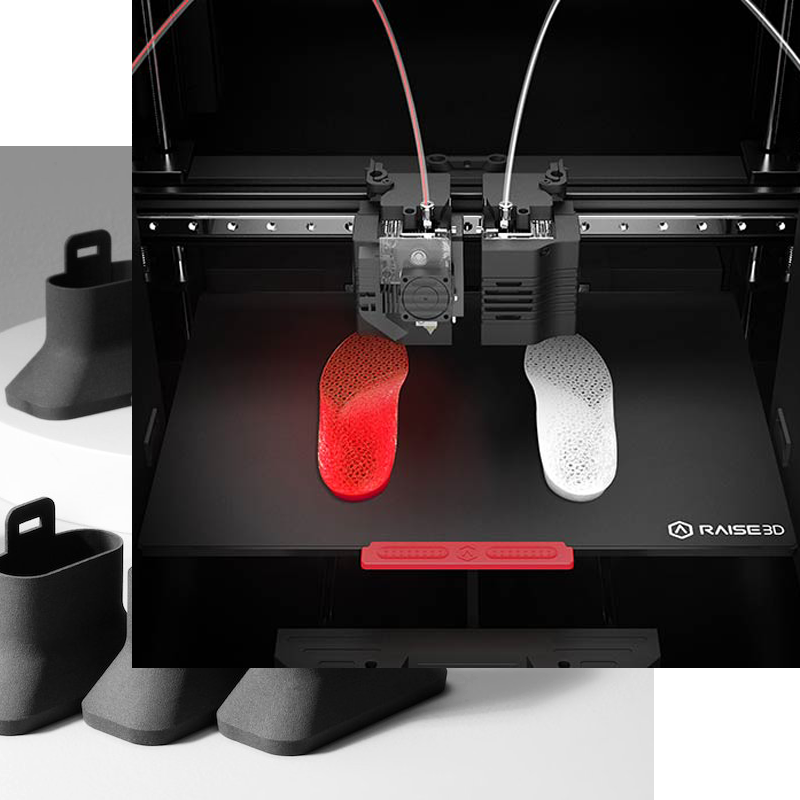

Example of SLA Printed Parts