Choose 3D materiAL

You are here » Home »

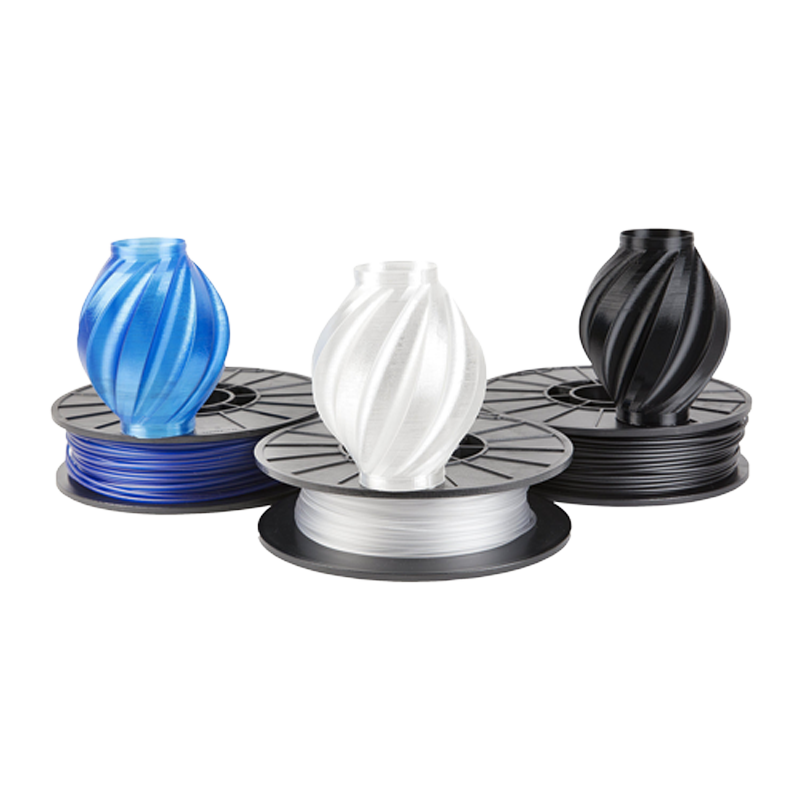

An inkjet printer uses ink cartridges to print. 3D printers use spools of filaments. There are several types of filaments, with different characteristics and properties (flexibility, resistance, ecological, etc.).

In order to help you choose the right material, we have prepared a guide with their technical characteristics.

PLA

PLA (polylactic acid) is the most used filament in 3D printing. Unlike ABS, it is biodegradable (made from corn starch), so it can be used to print objects that will be in contact with food products (plates, bowls).

It is increasingly used in the food industry to pack products such as fruits, vegetables, eggs, but also to replace tote bags and plastic bags distributed so far in the shops. On the other hand, it is quite sensitive to heat and water.

PLA is one of the easiest materials to print, its main feature being its low shrinkage, which does not necessarily require having a hot plate on the printer.

If it responds well to post-print processing like painting, it’s pretty hard to make it perfectly smooth. Indeed, the heat of friction of the sanding paper tends to melt the material.

There is a wide variety of colors that will allow you to give free rein to your imagination.

- Visual quality – 95%

- Impact resistance – 40%

- Heat resistance – 40%

- Moisture resistance – 40%

- Inter-layer adhesion – 95%

| Advantages of PLA | Disadvantages of PLA |

|

|

| Example of use | |

|

|

PLA PRO (PLA +)

PLA PRO (or PLA +) (Polyactic Acid), is an ecological filament that can eventually replace ABS. It has properties similar to ABS while being environmentally friendly. If you’re looking for a reinforced material that offers the same benefits as ABS while being mindful of environmental impact, PLA PRO is a top choice for your 3D printing projects.

- Visual quality – 90%

- Impact resistance – 60%

- Heat resistance – 80%

- Moisture resistance – 80%

- Inter-layer adhesion – 90%

| Advantages of PLA PRO (+) | Disadvantages of PLA PRO (+) |

|

|

| Example of use | |

|

|

ABS

It belongs to the family of thermal plastics (or thermoplastics) and therefore has a base of elastomers that makes it more flexible and resistant to shocks. In addition, it supports temperatures between -20 ° C and 80 ° C.

In addition to its excellent strength, ABS is reusable, perhaps polished or welded by chemical processes (using acetone). All these technical features make it the preferred material for engineers.

As for the PLA, it exists in a multitude of colors. On the other hand, it is not biodegradable.

- Visual quality – 75%

- Impact resistance – 80%

- Heat resistance – 90%

- Moisture resistance – 80%

- Inter-layer adhesion – 70%

| Advantages of ABS | Disadvantages of ABS |

|

|

| Example of use | |

|

|

PETG

It is the ideal material for parts intended to be in contact with food products. It is found for example in plastic bottles or in plastic glasses found in events such as festivals or concerts. In addition, PET is 100% recyclable.

There is a variant that is PETG (polyethylene terephthalate glycolized). The only difference is that the PET is brittle while the PETG is more flexible and therefore breaks less easily.

- Visual quality – 80%

- Impact resistance – 60%

- Heat resistance – 60%

- Moisture resistance – 100%

- Inter-layer adhesion – 80%

| Advantages of PETG | Disadvantages of PETG |

|

|

| Example of use | |

|

|

PC (polycarbonate)

Polycarbonate (PC) is a technical material that stands out for its high toughness, tensile strength and ability to withstand heat.

In addition to its use in 3D printing, it is used in the manufacture of CDs, goggles, screens and car headlight covers, among other applications.

In addition, Polycarbonates (PC) offer good suitability for 3D printing and are suitable for the creation of technical parts with high mechanical and thermal resistance.

- Visual quality – 70%

- Impact resistance – 80%

- Heat resistance – 100%

- Moisture resistance – 100%

- Inter-layer adhesion – 70%

| Advantages of PC | Disadvantages of PC |

|

|

| Example of use | |

|

|

FLEXIBLE MATERIALS

They are quite similar to PLA, but are made from TPU or TPE (thermoplastic elastomers). The use of these materials is very present in the world of fashion, but also in the industry that can enjoy a flexible material, strong and very pleasant to the touch.

As for PLA and ABS, flexible filaments are available in many colors to give vent to your imagination.

- Visual quality – 60%

- Impact resistance – 100%

- Heat resistance – 30%

- Moisture resistance – 100%

- Inter-layer adhesion – 60%

| Advantages of PLA | Disadvantages of PLA |

|

|

| Example of use | |

|

|

HYBRID MATERIALS

Today, we can print filaments based on cork, wood, bamboo, metal (bronze, copper, silver) and even organic materials such as rock, brick and cement.

The results obtained are simply breathtaking.